HANDAL DAN PROFESSIONAL

Menjadi perusahaan Konstruksi yang paling dipilih di daerah kami di Cilegon, Banten.

Email : Marketing@Quantumradjaperkasa.com – (+62) (254) 831-7055

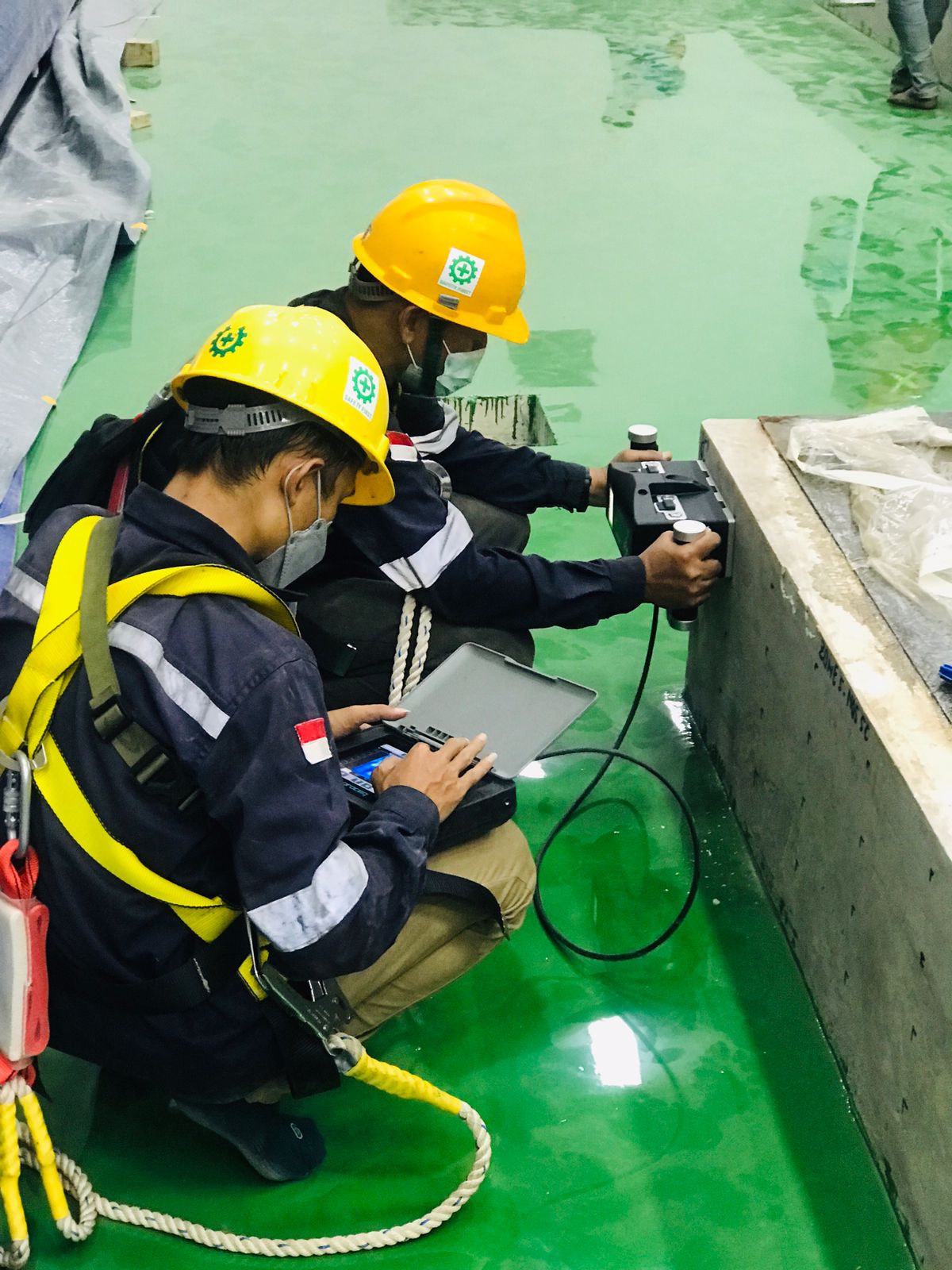

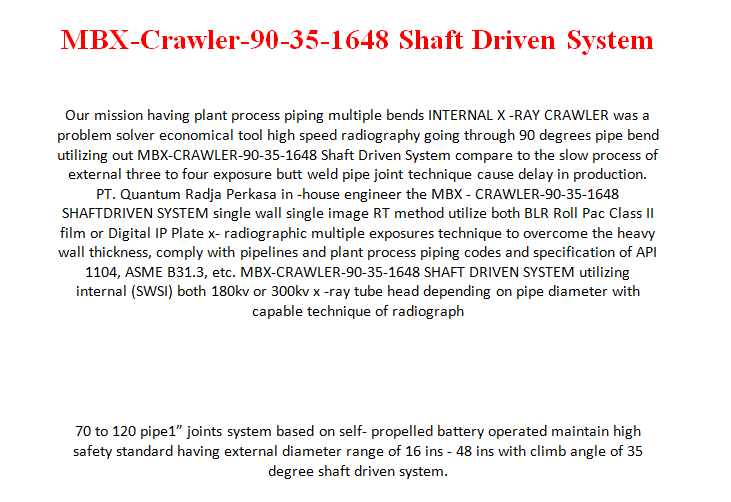

PT. Quantum Radja Perkasa uses Hardness testing with UCI Probe Suitable for low

finished surfaces. Surface finish equivalent to 30 grind or better.

The application of hardness testing enables you to evaluate a material’s properties,

such as strength, ductility and wear resistance, and so helps you determine whether a

material or material treatment is suitable for the purpose you require.

Ferrite testing is a fast, inexpensive, and accurate way to measure delta ferrite content in

austenitic and duplex stainless steels. Proper ferrite content provides a balance between

ductility, toughness, corrosion resistance and crack prevention.

Ferrite testing is a necessary process to avoid material failure in duplex stainless steel. If the

ferrite content is too high or low, it is harmful for the material. If the ferrite content is high,

the chance of corrosion increases.

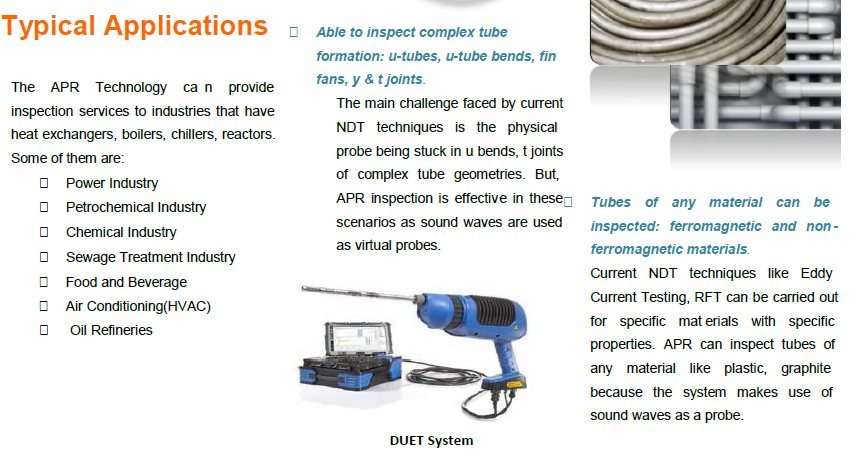

1. On Stream Corrosion Inspection

2. Rope Access NDT Engineering

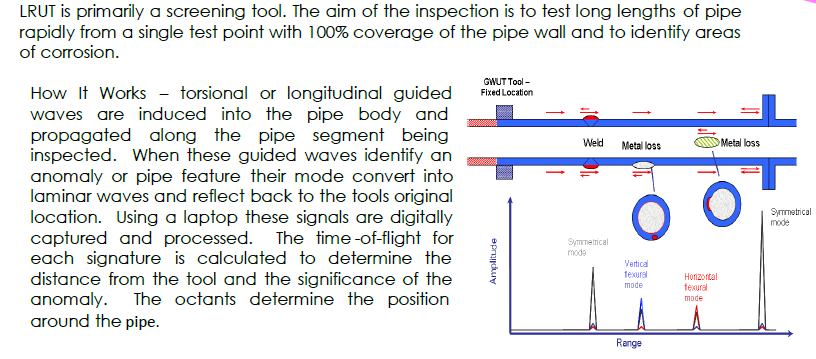

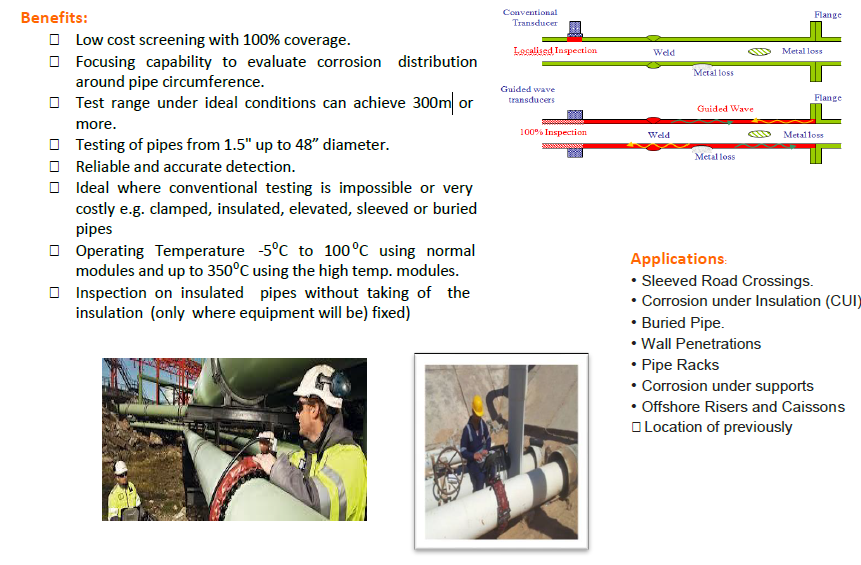

3. Long Range Ultrasonic Method

4. Digital Radiography Method.

Effective maintenance of drill pipe and associated hardware ensures the continued and safe

operation of a drilling rig.

An appropriate tubular inspection program helps identify integrity issues before they reach

criticality, preventing costly repairs and / or damage to personnel and the environment.

Professional inspections to thoroughly examine the tube body, as well as connections or end

areas are highly required in oil fields. Also checking for possible discontinuities and wall loss

in the tube body with EMI equipment.

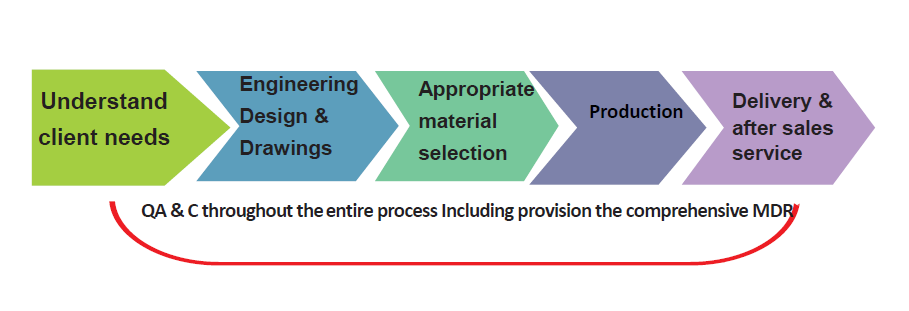

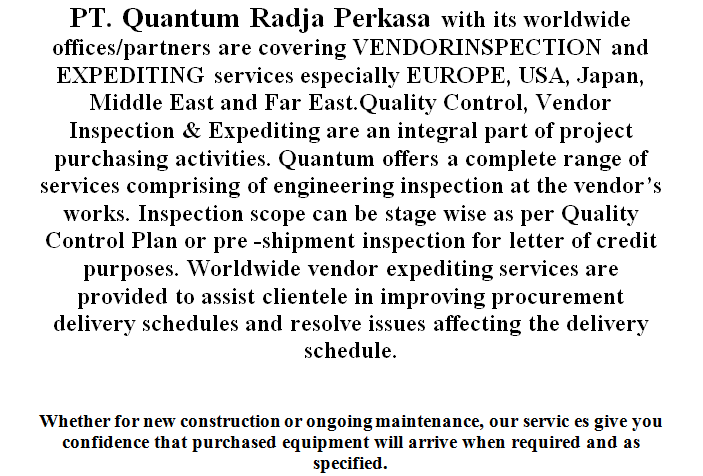

Since the safety, reliability and integrity are the aim of any end user/owner, so most clients require thatconstruction of oil and gas and other industrial plants necessitates that the procurement, engineering and construction activities are verified, validated and at times certified by an Independent. Third Party Inspection & Certification agency. This is where Quantum Radja Perkasa comes in and plays a major role. The certification activities require Project Design Verification, Procurement Inspections, Product Inspections, General Construction Inspections, and supporting Testing Services as well as QA/QC services. Quantum Radja Perkasa offers third-party inspection services through its offices worldwide as well as various registrations with internationally

recognized entities. Quantum Group reflect unbiased statement of fact reporting and con firms verification and inspection services to one or more internationally recognized codes, standards,

design specifications and specific technical project requirements. Our source inspection services at supplier and vendor sites for manufacturers, owners and other shareholders verify that the

equipment or goods have been manufactured in accordance with a client’s specifications and other applicable quality system requirement s as specified.

Precious Lite 2022 | All Rights Reserved. Precious Lite theme by Flythemes